Correia Transportadora 304 Metal Aço Inoxidável Correia Transportadora de Malha de Arame Espiral Correia Transportadora de Elos de Corrente de Alta Temperatura Para a Indústria Alimentar

As correias transportadoras de corrente de aço inoxidável são a escolha premium para aplicações de transporte exigentes onde a resistência à corrosão, higiene, durabilidade e tolerância à temperatura são críticas. Embora o investimento inicial seja maior, sua longevidade, baixas necessidades de manutenção (em comparação com o aço carbono corroído) e conformidade com os padrões sanitários as tornam soluções altamente econômicas em indústrias como alimentos, farmacêutica, química e ambientes industriais agressivos. A instalação, tensionamento, limpeza e manutenção preventiva adequados são fundamentais para maximizar seu desempenho e vida útil.

| Material |

SS304, SS316, SS316L, SS430, Fio galvanizado, personalizado |

| Diâmetro do fio espiral |

0,5 mm - 3 mm, personalizado |

| Diâmetro do fio da haste |

0,5 mm - 4 mm, personalizado |

| Passo espiral |

5-50mm, personalizado |

| Passo da haste |

5-50mm, personalizado |

| Largura |

Largura da correia de malha (sem corrente) / Largura da correia transportadora (com corrente) |

| Comprimento |

1m - 10m, personalizado |

Vantagens:

1. Resistência à corrosão superior: Resiste à ferrugem, produtos químicos, água, vapor e agentes de limpeza, tornando-o ideal para ambientes úmidos, úmidos ou corrosivos (alimentos, produtos químicos, marinhos).

2. Alta higiene e capacidade de limpeza: Superfícies lisas e não porosas evitam o crescimento bacteriano e permitem uma fácil. Essencial para aplicações alimentícias, de bebidas, farmacêuticas e médicas.

3. Resistência a altas temperaturas: Mantém a resistência e integridade sob calor significativo (por exemplo, fornos, lavadoras, esterilizadores, fundições).

4. Resistência e durabilidade: Suporta cargas pesadas, impactos e materiais abrasivos melhor do que muitas alternativas. Longa vida útil.

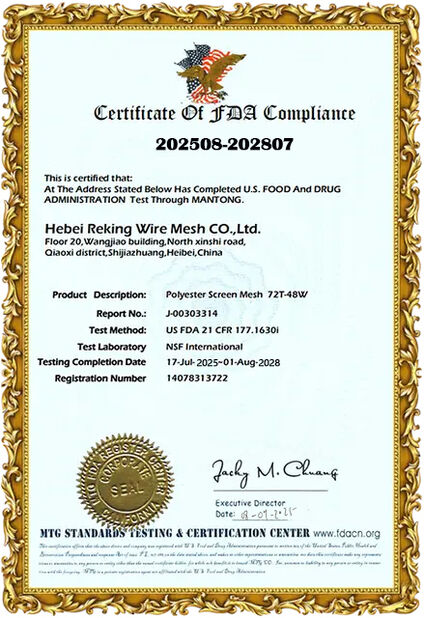

5. Design sanitário: Minimiza áreas onde detritos podem se acumular, atendendo a rigorosos regulamentos sanitários (FDA, USDA, 3-A).

6. Apelo estético: Mantém uma aparência limpa e profissional ao longo do tempo.

7. Resistência à oxidação e manchas: Desempenha bem ao ar livre ou em atmosferas propensas à oxidação.

Como usar:

1. Instalação: Monte firmemente a estrutura rígida, garantindo o alinhamento e nivelamento adequados. Instale a unidade de acionamento (motor, caixa de engrenagens) e a seção de cauda/recolhimento.

2. Tensionamento da corrente: Tensione corretamente a corrente usando o mecanismo de recolhimento – não muito apertado (desgaste excessivo) ou muito solto (escorregamento, descarrilamento).

3. Carregamento: Os produtos são normalmente carregados na superfície da corrente manualmente, por meio de alimentadores ou de equipamentos precedentes. Certifique-se de que a carga esteja dentro da capacidade e distribuída uniformemente.

4. Operação: Inicie o sistema de acionamento. As correntes se movem continuamente ou indexam (iniciar/parar) ao longo da esteira, transportando o produto. A velocidade é controlada por meio do acionamento.

5. Descarregamento: Os produtos são descarregados no final (ou pontos intermediários por meio de empurradores/desvios) manualmente, por gravidade ou em outra correia transportadora.

Limpeza e Manutenção:

Limpeza regular: Use água, vapor ou sanitizantes aprovados. A lavagem com alta pressão é comum. Certifique-se da drenagem adequada.

Lubrificação: Use lubrificantes de grau alimentício ou compatíveis com moderação, se necessário (alguns projetos usam correntes autolubrificantes ou funcionam a seco). Evite contaminação.

Inspeção: Verifique regularmente o desgaste da corrente (esticamento), elos danificados, rodas dentadas gastas, tensão adequada, condição dos rolamentos e integridade da estrutura.

Substituição de componentes: Substitua correntes, rodas dentadas, guias e rolamentos gastos imediatamente para evitar falhas.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!